We have a vast number of machines, composed of high-tech equipment and based on the principles of lean manufacturing, obtaining the highest efficiency values.

Our high-tech machines are specially designed for high-pressure aluminium castings with high machining and tool change speeds, ensuring they reach tight tolerances at a micron level with precise dimensions and quality.

Our production at a glance:

- Interactive and mobile project teams

- Tool specialists with advanced knowledge

- Skills in Hydraulics, Welding and Electrical

- Digital process control and quality monitoring

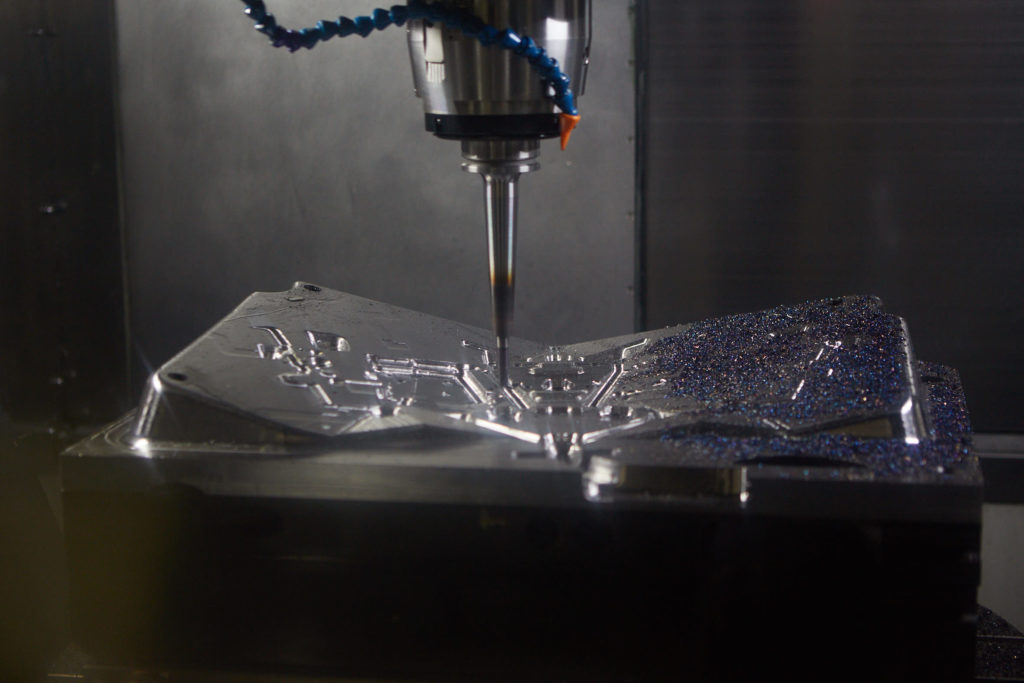

- 3D CNC mechanical processing with tool changer

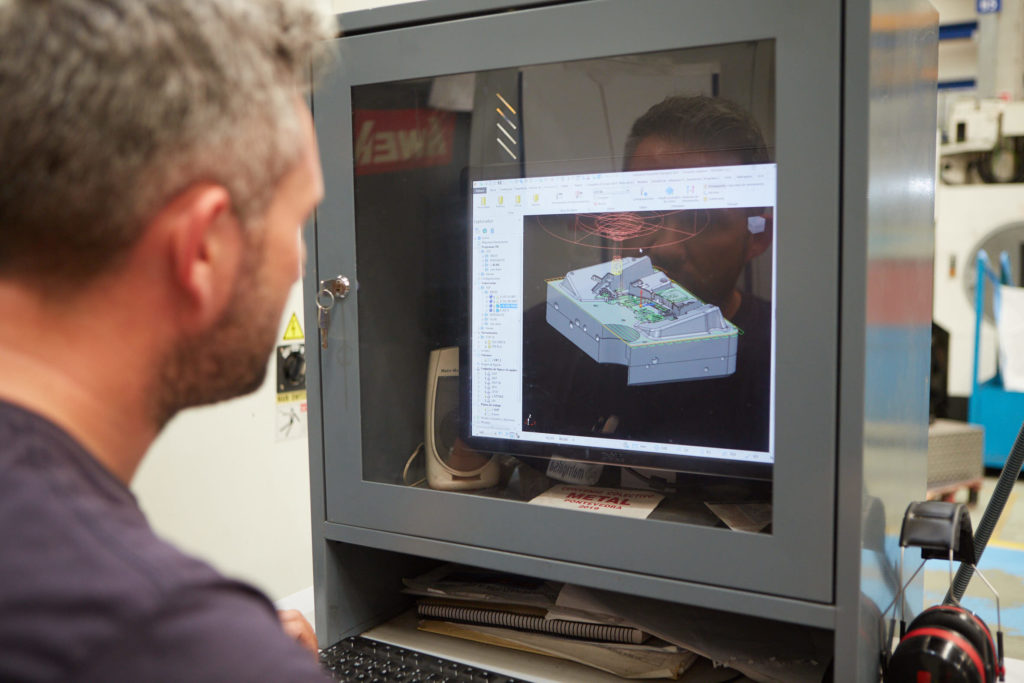

- CAM – CNC equipment with rotation system and WOP

- 5-axis simulation milling

- Collision monitoring and machine data with call system

- Carriageways up to 3 m

- Table loading up to 20 T

- Crane systems up to 40 T

- Puncture press – 3 m x 3 m, 4000 kN

Milling

Grinding

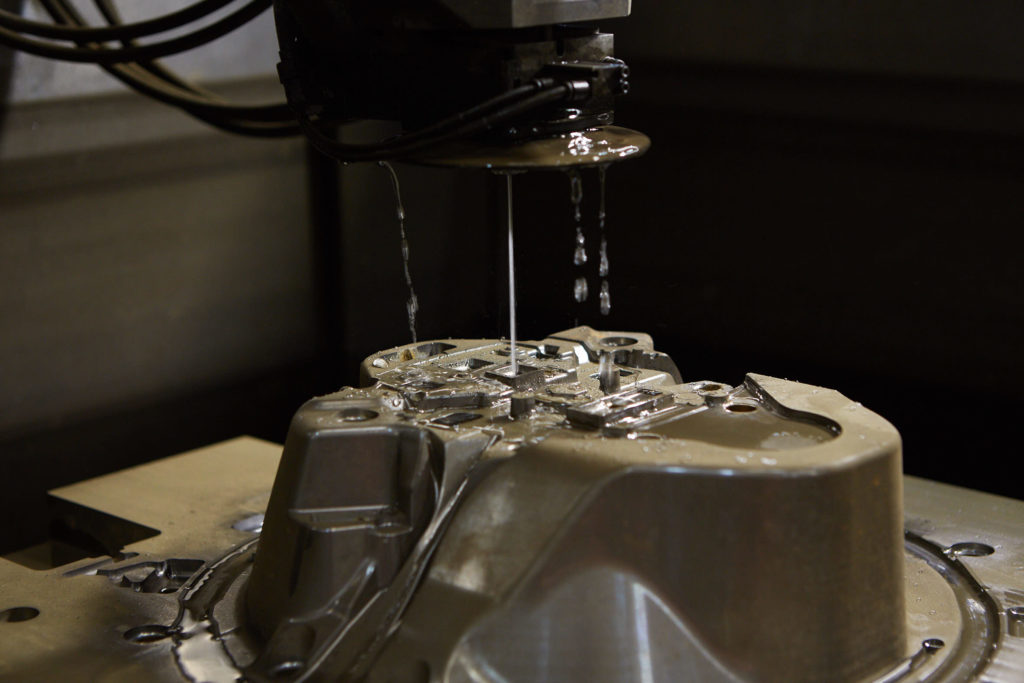

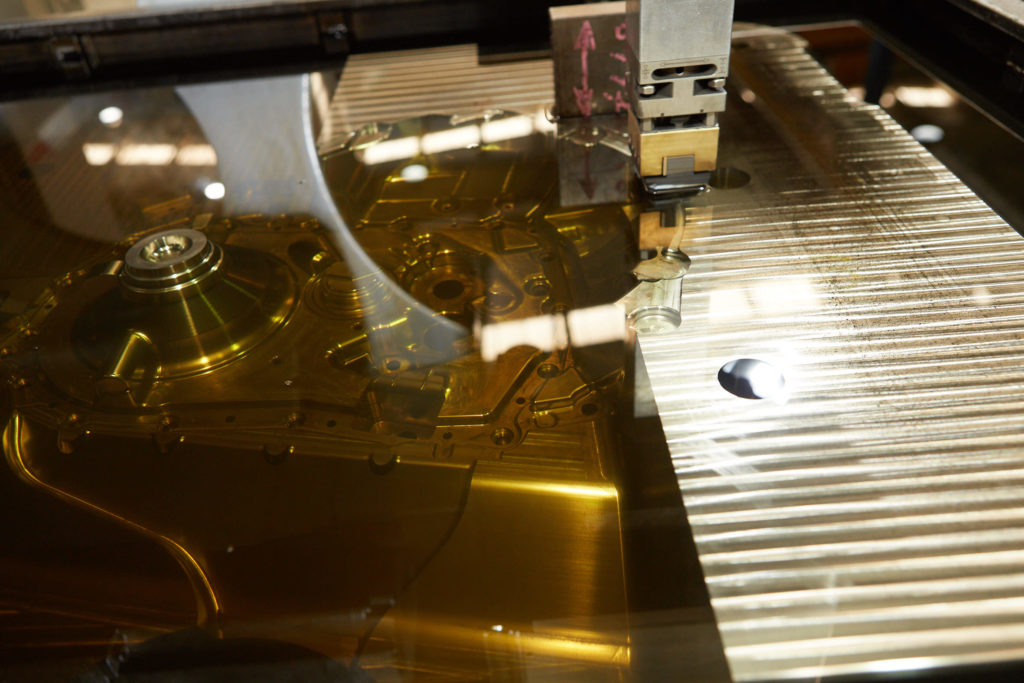

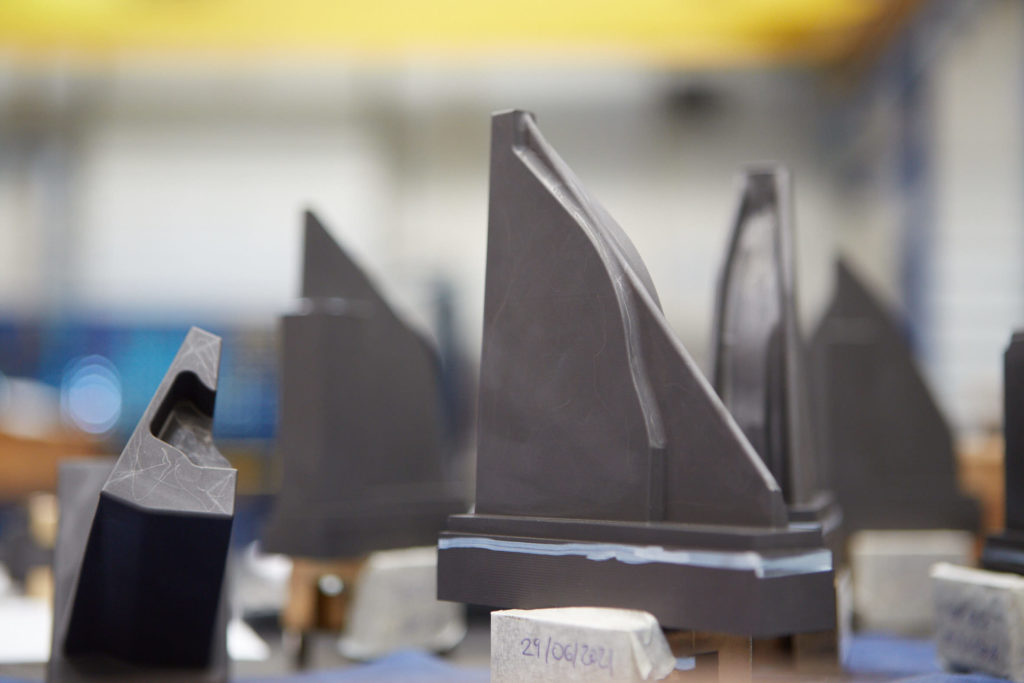

EDM Electrical Discharge Machining

Assembly

Our assembly process obeys a rigor of high quality, which is endorsed by our specialized assembly team with vast years of experience.

We also have at Your disposal all the means that guarantee the mechanical assembly with the greatest possible agility, such as:

- Tool closure presses

- Tool Turner 50 Tn

- Drilling and threading machines

Auxiliary Processes

We also guarantee a large number of additional processes that are applied to components based on customer needs and specifications, such as:

- Heat treatment, from stabilized, to tempered, all with the certification of the material.

- Ultrasonic washing system, with ultrasonic drying process, rinsing option and corrosion protection.

- Certified welding process, with welding stress relief process.

- Various blasting processes.

- Performing the tool leak test with detailed reports.

- Mechanical testing of materials carried out by local external laboratories.