MATRIGALSA’s wide range of competence makes us an excellent partner for tool solutions for all foundry processes.

In addition to the production and maintenance of high-quality and reliable tools, we accompany the tasks related to the tool and the casting process from the first idea to series production.

Development Partner

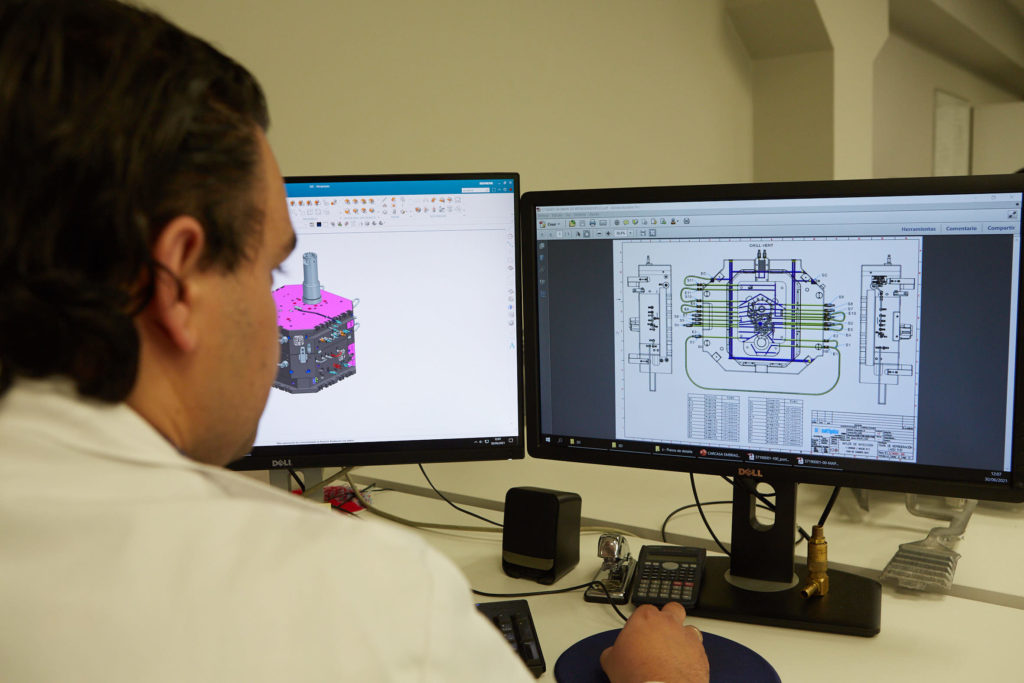

We are Your development partner carrying out decisive innovations together with You! Our multilingual project managers are tool specialists and understand the relevant issues. This team is the direct contact person and guarantees the optimal combination of service and production of high-tech tools. We are also known for developing automation solutions for combined casting processes, integrating innovative Industry 4.0 solutions to your casting tools in your casting process. We work with the main design software on the market, and for each project we select the ideal software for our client. Here is an overview of our CAD potential:

CAD-Software:

- CATIA

- CREO

- NX

- SOLID WORKS

More than 14 CAD stations

Fully parameterized CAD design

Tool and Process Optimization

MATRIGALSA is Your partner for the optimization of tools and processes, we are specialists in tool solutions for a wide variety of metal casting processes with almost 40 years of experience in the market. In combination with the most modern analysis and simulation tools, we advise our clients on the optimization of tools and processes. State-of-the-art simulation tools are used specifically, from core process simulation to casting simulation with flow modules.

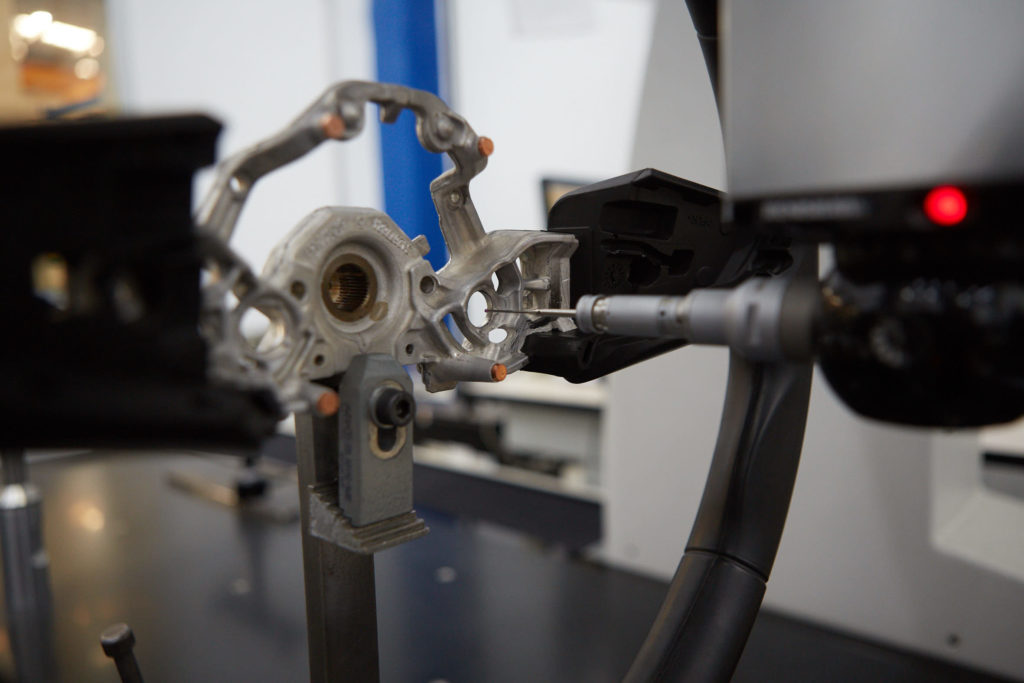

Quality Assurance

MATRIGALSA is synonymous with quality in the production and maintenance of tools!

Our processes are under control at all times, starting with the inspection, development, construction, process monitoring, manufacturing and delivery of incoming goods. For us, quality of service also means:

“Competent advice, support, a high degree of flexibility and help. Based on qualified employees and a high degree of customer orientation”.

Our goal is continuous improvement, the basis for this is a constant optimization of production facilities, processes, skills and knowledge, as well as the obligation to expand within the scope of possibilities and economic success with “cutting edge technology “.

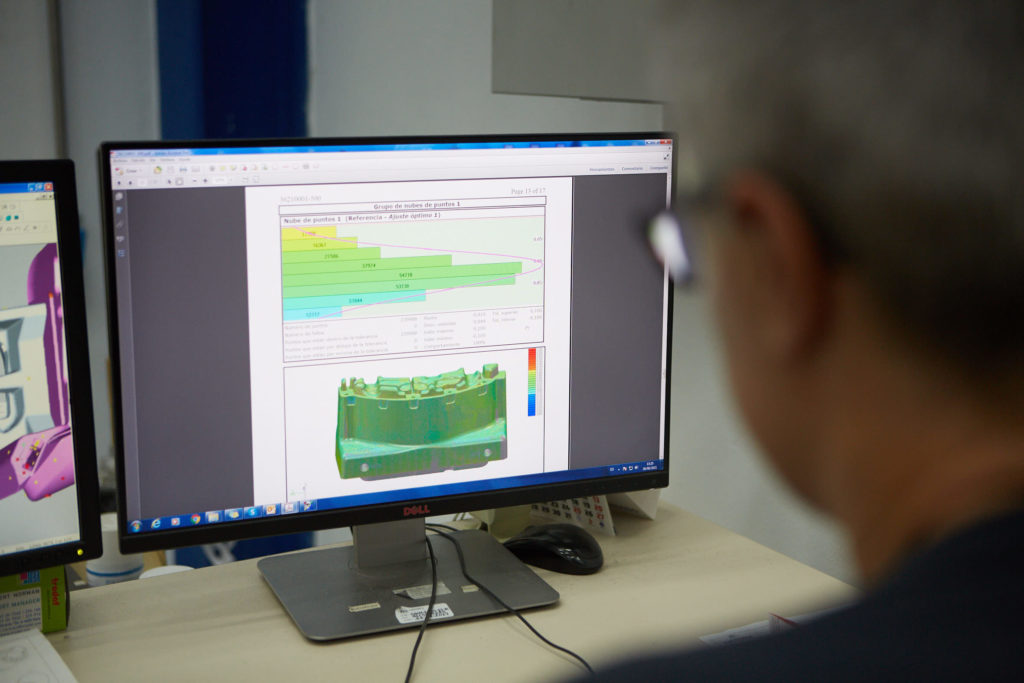

Software

Reporting and visualization using false colour visualization, with:

- PCDemis

- Power Inspect

- Geopack

Supplement to means of control

- Quality assurance in an acclimatized measuring room

- 100% measurement of relevant areas

- Mobile laser scanner

- Profiles projector

- Digital Durometer

Quality assurance supplement

- Tensile test

- Compression test

- Fatigue tests

- Torque tests

- Welding tests

Repair and Maintenance

We offer You individual maintenance and repair plans with an integrated “management tool system”. With “predictive maintenance” and the associated network in Industry 4.0 systems, maintenance cycles are effectively extended.

At MATRIGALSA we work hand in hand with our clients, in emergencies, we react extremely flexibly, through our fast reaction times and implementation we solve their tool problems, for this we use a logistics network that is used where the tasks of maintenance and repair. Very fast response times are required, we guarantee the reduction of downtime.

Service highlights:

- Tooling maintenance work up to 60 t.

- Personalized customer service

- We manage and carry out

- Engineering changes

- Tuned

- Repairs and spare parts manufacturing

Turnkey service

As Your ideal casting partner, MATRIGALSA can offer a wide range of turnkey services:

- Tool testing capability in:

-

- High pressure Die-Casting (HPDC), in aluminium or magnesium, with or without vacuum system

- Low pressure casting (LPDC)

- Sand core tool test, cold process

- Complete production of the pre-series, including the final machining, with the respective quality validations (X-ray analysis, penetrant liquid analysis and full CMM report)

- Additive manufacturing of metals and sand

- Manufacture of tools of:

-

- Mounting

- Handling

- Machining

- Quality

For more information on these and other solutions, contact us.